Anhui Ancourage Scientific Co., Ltd. To Be your Best Laboratory Instruments Supplier!

Toggle Navigation

ACG-AM700 Jaw Crusher

AM700 Jaw Crusher, is suitable for high degree of size reduction,larger amounts or continuous crushing operations. Fast precommmution for mediumhard hard brittle.lt can be applied not only for samples with less batch processing but also for continuous processing of larger samples.Escape-free hopper with cleaner interface,achieve good effect of dust removal.The front door of the grinding cavity can be opened directly,easily cleaning. Gap width adjustment, digital display . Zero point adjustment ensures repeatability of experimental results.

Performance Advantages

A.High throughput, high degree of size reduction.

B.The maximum feed size ( up to 120mm ).

C.High final fineness (down to D90 <2 mm).

D.No-rebound feed hopper with dust extraction unit.

E.Zero-point adjustment for wear compensation.

F.The front door of the grinding cavity can be opened directly,easy to clean.

G.A safety lock device for the grinding cavity and the collection tank.

H.Gap width with handwheel.

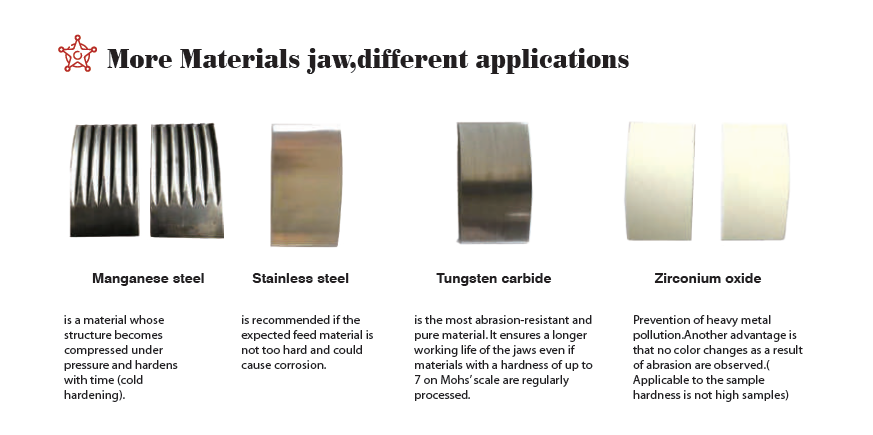

I.Different materials jaws can be used for different applications.

Technical Information

| Technical parameter | ACG-AM700 Jaw Crusher |

| Sample Type | Medium-hard,hard,brittle |

| Feed Size | Max. 120×90mm |

| Final Fineness | D90<2mm |

| Collector Capacity | 10L、30L |

| Throughput | 300Kg/h |

| Setting Time | 2 mode optional,1s-7h59min59s, continuous |

| Setting Gap width | 0-40mm |

| Gap width Display | Scale |

| Zero Point adjustment | Yes |

| Dust Extraction unit | Yes |

| Jaw Material | Manganese steel, stainless steel, tungsten carbide,Antiheavy metal pollution steel |

| Jaw Width | 146mm |

| Speed | 253rpm Customized |

| W×H×D | 600mm×1340mm×770mm |

| Net Weight | Approx. 420Kg |

| Electrical Parameters | 380V/3000W |