Anhui Ancourage Scientific Co., Ltd. To Be your Best Laboratory Instruments Supplier!

Toggle Navigation

ACG-AM300/ACG-AM300S Cutting Mill

AM300S Cutting mill,suitable for soft, medium-hard、toughness and fibrous samples, quick grinding , More efficient cutting speed can be readily solved when dealing with heat sensitive samples.Three-phase motor output strongly, high torque cutting makes AM300S in the face of extremely complex samples (such as solid waste) more excellent. Stepless speed regulation can be adapted to various samples. The motor brake is stopped quickly. When the grinding cavity is opened, the instrument can not operate and the safety is ensured. In addition, AM300S can be equipped with cyclone separator,suitable for fibrous or light weight samples, improve grinding efficiency.

Performance Advantage

A.3000W motor drives efficiently to ensure effective grinding of samples.

B.100-3000rpm is adjustable to suit different samples.

C.Multiple continuous cutting edges in the grinding chamber are short the grinding time of the sample.

D.Plug-in Type rotor and bottom sieve , easy to clean.

E.Low heat build-up, suitable for heat-sensitive sample.

F.Large feeding quantity, up to 80L/h , final fineness 100μm-20mm,suitable for different requirement.

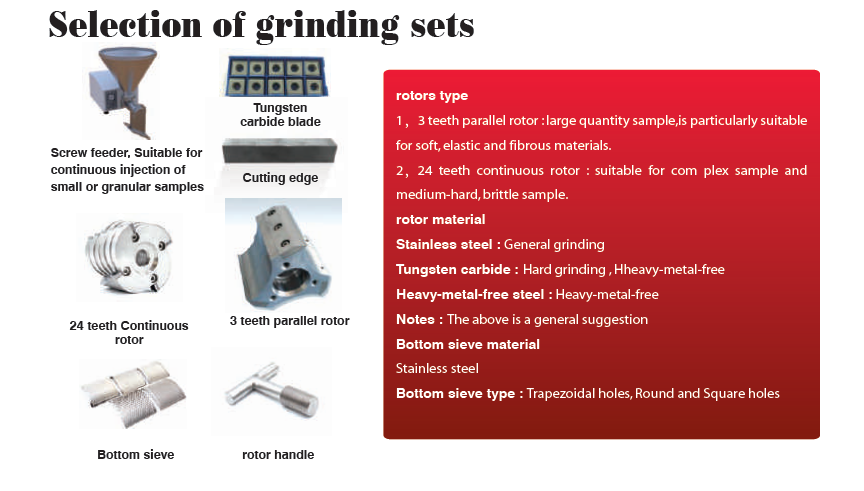

G.Different material rotors and ring sieves.

H.Digital display ensures repeatability of sample result.

I.The control panel reads the load directly in class, which makes it easy to adjust the feed Speed and feed rate.

J.The sample booster can make the sample easier to enter the grinding cavity for grinding.

K.Escape-free hopper, dust-free design,eazy to clean.

L.The instrument has a sensing device , operation safety.

M.The motor has a brake system , stop quickly.

N.AM300S designed with aerated grille to facilitate sample collection.

O.Bracket of AM300S is aluminum,Separable from the host,Easy to transport.

Technical Information

| Technical parameter | ACG- AM300 Cutting Mill | ACG-AM300S Cutting Mill |

| Sample Type | Soft, Medium-hard, Toughness, Elastic, Fibrous | |

| Feed Size | ≤70 x 90mm | |

| Final Fineness | About 100μm-250μm ( Depending on the nature of the sample and the grinding environment) | |

| Feeding Quantity | 80L/h | |

| Setting Speed | 100rpm-3000rpm | |

| Grinding Environment range | Dry | |

| Collection Device | 0.5L, 3L, 5L, 30L | |

| Rotor Material | Stainless steel, Tungsten carbide, Heavy-metal-free | |

| Rotor Teeth | 3 teeth parallel section rotor/24 teeth Continuous rotor | |

| Bottom Sieve holes(stainless) | Conidur holes 0.25mm x 0.5mm x 1.0mm x 1.5mm Round or Square holes 2.0mm、4.0mm、6.0mm、 8.0mm、10.0mm、20.0mm | |

| Hopper | Dust-free hopper, Screw feeder | |

| Cyclone Separator | Optional 0.5L,1L,3L,5L,30L | |

| WxHxD | 650mm x 1400mm x 750mm | 455mm x 1450mm x 715mm |

| Weight Net | Approx. 150kg | |

| Electrical Parameters | 380V/50hz,3KW 380V/3000W | |